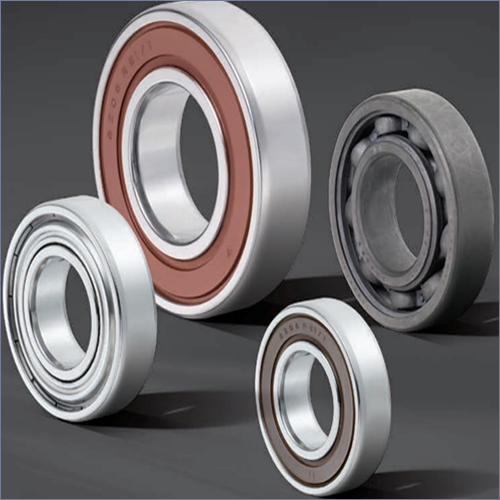

NTN High Temperature Bearings

Product Details:

- Usage Industrial

- Product Type High Temperature Bearings

- Color Silver

- Material Steel

- Ball Bearing Type Temperature Bearings

- Roller Bearing Type Other

- Click to View more

NTN High Temperature Bearings Price And Quantity

- 1 Piece

- 20.00 - 40.00 INR/Piece

NTN High Temperature Bearings Product Specifications

- Temperature Bearings

- Steel

- High Temperature Bearings

- Industrial

- Other

- Silver

NTN High Temperature Bearings Trade Information

- 25000 Piece Per Month

- 3-5 Days

- All India

Product Description

Backed by its unique experience in the bearing field, the NTN-SNR group has developed a range of ball bearings that survive under extreme operating conditions. Indeed, new equipment is often subjected to ever increasing speed and/or operating temperature requirement NTN-SNRs High Temperature range now broadens the technical range of solutions provided to meet the greatest variety of applications

Application examples:

Electric motors, textile machines, ac generators, heating pumps, refrigeration systems, industrial ventilation, Heater units / fan assemblies, Driers, Alternators, Hi temperature ovens and kilns, couplings, dryers, compressors, trucks used in kilns for brick making, in furnaces for the ceramic industry, in rollers in working conditions at elevated temperatures in the steel manufacturing industry, aluminium manufacturing, glass manufacturing, Steel industry, Etc.

Design features.

To meet the most stringent requirements, the TOPLINE range benefits from all of SNRs latest technological innovations:- Optimized internal geometry, with tighter tolerances and greater precision.

- Heat treatment adapted to operating conditions.

- Lubrication with grease selected to enhance operating performance.

Two possible types of protection:

Seals: highly effective against outside contamination and temperature, with a seal made of viton.

Shields: suitable for higher speeds of rotation, more cost effective

- Large radial clearance: Clearance is sufficient to compensate for differential thermal expansion between the inner and outer rings of the bearing and/or surrounding parts.

- Heat treatment with stabilization temper.

- Pressed steel cage.

- Recessed markings on both rings. Marking maintains proper identification of bearings at all times regardless of operating conditions

Extreme conditions, extreme controls

- The NTN-SNR have focused on this critical criterion through consideration of:

- Physical/chemical characteristics: upper and lower operating limits, drop point, extreme pressure properties, etc.

- Mechanical features: stability at various temperatures, in the presence of water, high temperature capabilities, resistance at high speed and/or low torque

- Proven performance under actual operating conditions. NTN-SNR has worked with the largest industrial manufacturers. A guarantee of reliability

Bearing Considerations for High-Temperature Applications

- If your bearings cant stand the heat, your high-temperature applications can be in trouble. Extreme heat can have many adverse effects on bearings, which can put applications in high-temperature environments at risk without proper heat stabilization, which includes everything from rolling mills to chains that pass through an oven.

- Traditional bearings supplied can typically operate in temperatures up to 300 degrees Fahrenheit. Any temperatures higher than that can negatively impact the efficiency and effectiveness of those bearings through a wide variety of problems.

- Potential Heat Issues for Bearings

Additional Wear and Tear

Over time, excess heat can change the microstructure of the steel causing a reduction in the estimated life of the bearing. The friction created when a bearing rotates creates heat, which can make an already hot environment even more extreme. The resulting heat can cause a myriad of problems and can change natural wear and tear into unnatural wear, ruining your bearing in the process.

Expansion

Heat causes metal to expand, which can create warping issues. When the metal in a bearing expands, it can reduce the clearance between the ball and the raceways. This change in clearance can cause the bearing to tighten, which can eventual force it to seize up and fail.

Improper Seals

Like the rest of the bearing, seals need to be stabilized to survive extreme temperatures. Traditional rubber seals are only rated for certain temperatures, so extreme temperature can render these seals useless without the proper material or stabilization. This can also cause bearing grease to purge the oil which can and migrate onto other components. Depending on the application, this can be an unwanted side effect, especially if the grease falls onto new products.

Improper Grease

- Like seals, special greases are required for high-temperature environments. Standard greases are effective up to 300 degrees, but will purge all oils leaving a dried-up soap base in hotter conditions. Without that grease, bearings are subject to more friction, leading to even increased wear and shorter life.

- Bearing Considerations for High-Temperature Environments

- There are some considerations to make when choosing heat-treated bearings.

Lower RPMs

As we mentioned before, the natural friction caused by rotation creates heat. Heat stabilized bearings combat this by operating at a lower RPM than their standard bearing counterparts. As a result, you will want to consider the RPMs for your high-temperature bearing options to make sure they match the needs of your applications. Some bearing manufacturers offer multiple versions of the same bearing so that you can pick and choose which temperature range best matches your application.

Softer Metals

- As you modify the heat treatment for the appropriate temperature range the hardness of the steel with be reduced to stabilize the steel. Traditional bearings that are rated for up to 300 degrees have a Rockwell hardness range of 60 to 64. The hardness rating will be adjusted based upon operating temperatures for heat- stabilized bearings. With lower steel hardness the potential for increased wear is greater at higher speeds, so keep that in mind when selecting your high-temperature bearing solutions.

- Due to the need for heat stabilized steels, finding a bearing with proper load support is also crucial. The higher the operating temperature inherently support lower loads, so alternate solutions may be necessary. One suggestion is switching to a material with a higher natural temperature range. For example, a 440 stainless steel bearing can be used to meet higher load needs when a heat-treated chrome bearing isnt enough.

Find the Right Bearings for Your Applications

Like many types of bearing failure, overheating is avoidable when you choose the right product for your applications. High-temperature bearings allow your applications to operate as they should in extreme environments, saving you from spending time and money on costly maintenance and repairs.

Other Products in 'NTN Ball Bearings' category

|

BAREWELL TRADERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS